Cool Solution

Cool to the Core!

While attending an automotive technical seminar recently, the topic of overheating and the various causes and current solutions came up during the lunch discussions between sessions. I was disturbed to hear conjecture and the misinformed passing on “common knowledge” to newcomers attending their first technical seminars.

This is my attempt to clear the air and explain what’s going on these days with overheating and the phenomenon known as “thermal transference”.

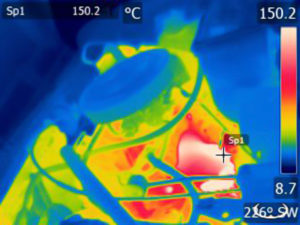

Thermal transference is the flow of heat in a body, automatic transmissions in this case, to or from external surroundings either by conduction, convection or radiation. More specifically, the heat generated at frictional surfaces, such as planetary gear sets, clutch packs, vane pumps, sheaves and belts, etc., is transferred from a high temperature area to a lower temperature area. In an automatic transmission, the fluid acts as a carrier through which heat is transferred. This transfer of heat changes the energy of both objects involved in the heat transfer. To protect the transmission from damage, built-up heat needs to be removed. This is the function of the auxiliary cooling system and in most applications, this is done by an external cooler. These systems can be configured as externally water cooled (bottom of engine radiator) or air cooled (aluminum finned heat exchanger) systems that cool the hot transmission fluid. Heat removed this way is called “convection heat transfer” by motion of a fluid, where in the cooler, moving fluid causes the heat to move away from the source of the heat, carrying the heat energy with it. In automatic transmissions, the fluid is pumped through the cooling system to the radiator (or heat exchanger) where the heat is transferred to the metal wall (aluminum in today’s cooling systems) of the heat exchanger (water or air type) and is released to the atmosphere (air flowing over the fins of the radiator or heat exchanger) by “conduction heat transfer”. If one end of an aluminum cooling fin is at a higher temperature, then heat energy will be transferred through the cooling fin toward the colder end because the high-speed heated particles will collide with the slower particles causing the transfer of heat energy to the slower ones. These fins then discharge the heat to the atmosphere by means of “heat radiation” (with radiation being defined as the emission of electromagnetic waves which carry the energy away from the emitting object). Simply stated, the heat is removed from the transmission by pumping the hot ATF through the heat exchanger in the liquid (or air) cooled heat exchanger where it is cooled, then returns as cooled fluid to the transmission. The goal is obviously to reduce operating temperatures and prevent overheating. Unfortunately, overheating can be caused by anything that decreases the cooling systems ability to absorb, transport, and dissipate heat. Examples of this are low coolant level, poor heat conductivity due to sludge or deposits, poor airflow through the radiator, a bad water pump, or any of the many problems that affect the liquid cooled cooling systems of most vehicles. In many cases today, radiators are barely able to cool the transmission even when everything is working correctly.

Thermal transference is the flow of heat in a body, automatic transmissions in this case, to or from external surroundings either by conduction, convection or radiation. More specifically, the heat generated at frictional surfaces, such as planetary gear sets, clutch packs, vane pumps, sheaves and belts, etc., is transferred from a high temperature area to a lower temperature area. In an automatic transmission, the fluid acts as a carrier through which heat is transferred. This transfer of heat changes the energy of both objects involved in the heat transfer. To protect the transmission from damage, built-up heat needs to be removed. This is the function of the auxiliary cooling system and in most applications, this is done by an external cooler. These systems can be configured as externally water cooled (bottom of engine radiator) or air cooled (aluminum finned heat exchanger) systems that cool the hot transmission fluid. Heat removed this way is called “convection heat transfer” by motion of a fluid, where in the cooler, moving fluid causes the heat to move away from the source of the heat, carrying the heat energy with it. In automatic transmissions, the fluid is pumped through the cooling system to the radiator (or heat exchanger) where the heat is transferred to the metal wall (aluminum in today’s cooling systems) of the heat exchanger (water or air type) and is released to the atmosphere (air flowing over the fins of the radiator or heat exchanger) by “conduction heat transfer”. If one end of an aluminum cooling fin is at a higher temperature, then heat energy will be transferred through the cooling fin toward the colder end because the high-speed heated particles will collide with the slower particles causing the transfer of heat energy to the slower ones. These fins then discharge the heat to the atmosphere by means of “heat radiation” (with radiation being defined as the emission of electromagnetic waves which carry the energy away from the emitting object). Simply stated, the heat is removed from the transmission by pumping the hot ATF through the heat exchanger in the liquid (or air) cooled heat exchanger where it is cooled, then returns as cooled fluid to the transmission. The goal is obviously to reduce operating temperatures and prevent overheating. Unfortunately, overheating can be caused by anything that decreases the cooling systems ability to absorb, transport, and dissipate heat. Examples of this are low coolant level, poor heat conductivity due to sludge or deposits, poor airflow through the radiator, a bad water pump, or any of the many problems that affect the liquid cooled cooling systems of most vehicles. In many cases today, radiators are barely able to cool the transmission even when everything is working correctly.

Without the addition of external coolers and larger sumps, the ability of the vehicle owner to reduce automatic transmission temperatures becomes limited.

The only effective alternative left is aftermarket additives that improve heat transfer  properties in the transmission fluid to more effectively remove heat and the LXE Technology in LUBEGARD’s ATF products does just that. In transmissions, heat is absorbed from the frictional surfaces through the bulk oil and is carried to the radiator or heat exchanger for discharge. The molecular makeup of LXE Technology provides a very long linear chain of carbon atoms that are surrounded by oxygen atoms. The oxygen atoms have a negative charge, thereby attracting the LXE molecule to a metal surface. When these molecules are heated by moving internal components, the attraction of the atoms moves the heat outward carrying it to the case or radiator/heat exchanger where the heat energy is discharged. The result is lower operating temperatures that will extend the life of the fluid and transmission. In addition, the thermal and oxidative stability of the fluid is enhanced, which prevents burning and deposit formation. This makes LXE the most heat stable transmission fluid technology currently sold. Exceptional lubricity and heat resistance are why LXE Technology remains the only technology endorsed by multiple OEM’s and used by transmission professionals worldwide.

properties in the transmission fluid to more effectively remove heat and the LXE Technology in LUBEGARD’s ATF products does just that. In transmissions, heat is absorbed from the frictional surfaces through the bulk oil and is carried to the radiator or heat exchanger for discharge. The molecular makeup of LXE Technology provides a very long linear chain of carbon atoms that are surrounded by oxygen atoms. The oxygen atoms have a negative charge, thereby attracting the LXE molecule to a metal surface. When these molecules are heated by moving internal components, the attraction of the atoms moves the heat outward carrying it to the case or radiator/heat exchanger where the heat energy is discharged. The result is lower operating temperatures that will extend the life of the fluid and transmission. In addition, the thermal and oxidative stability of the fluid is enhanced, which prevents burning and deposit formation. This makes LXE the most heat stable transmission fluid technology currently sold. Exceptional lubricity and heat resistance are why LXE Technology remains the only technology endorsed by multiple OEM’s and used by transmission professionals worldwide.